Guide to Conveyor Chain Drive Systems

By:Admin

With a focus on quality, reliability, and innovation, Conveyor Chain Drive has been a trusted name in the industry for over 50 years. The company is dedicated to providing cutting-edge solutions that meet the evolving needs of their customers, and the introduction of the new [Conveyor Chain Drive] is a testament to their ongoing commitment to excellence.

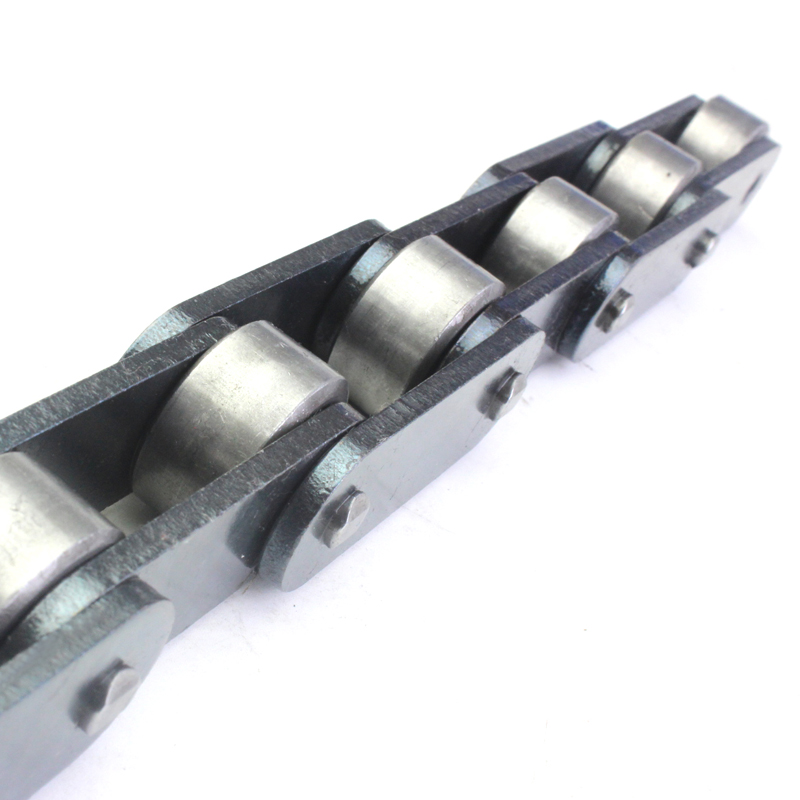

The [Conveyor Chain Drive] is designed to deliver high performance in demanding industrial environments. Its robust construction and precision engineering ensure maximum durability and reliability, making it ideal for heavy-duty applications. The chain drive system is also highly versatile, capable of accommodating varying speeds and loads, making it suitable for a wide range of conveyor systems.

One of the key features of the [Conveyor Chain Drive] is its advanced lubrication system, which ensures smooth operation and extends the lifespan of the chain drive. This innovative design reduces maintenance requirements and downtime, resulting in increased productivity and cost savings for the end user. In addition, the chain drive is equipped with safety features to prevent accidents and ensure the wellbeing of workers.

The [Conveyor Chain Drive] is available in a range of sizes and configurations to accommodate different conveyor setups and requirements. Customization options are also available to meet specific customer needs, further demonstrating Conveyor Chain Drive's commitment to delivering tailored solutions to their clients.

In addition to the launch of the [Conveyor Chain Drive], Conveyor Chain Drive also offers a comprehensive range of conveyor components, systems, and accessories to provide complete solutions for material handling and processing needs. From roller chains and sprockets to conveyor belts and accessories, the company's extensive product line caters to a diverse range of industries, including manufacturing, food processing, logistics, and more.

With a global presence and a strong reputation for excellence, Conveyor Chain Drive is well-positioned to serve the needs of industrial customers worldwide. The company's dedication to quality, innovation, and customer satisfaction has earned them the trust and loyalty of a broad customer base, further solidifying their position as a leader in the industry.

The launch of the [Conveyor Chain Drive] represents another milestone in Conveyor Chain Drive's ongoing commitment to delivering cutting-edge solutions to their customers. The company's investment in research and development, as well as their continuous improvement efforts, ensure that they remain at the forefront of technological advancements in the industry.

Looking ahead, Conveyor Chain Drive is poised to continue its trajectory of success, driven by a passion for innovation and a dedication to meeting the evolving needs of their customers. As the industrial landscape continues to evolve, Conveyor Chain Drive remains a steadfast partner for businesses seeking reliable, efficient, and high-performance conveyor solutions.

In conclusion, the introduction of the [Conveyor Chain Drive] solidifies Conveyor Chain Drive's position as a leading provider of industrial conveyor systems and components. With a focus on quality, innovation, and customer satisfaction, the company is well-equipped to meet the diverse needs of industrial customers around the world. As Conveyor Chain Drive continues to push the boundaries of industrial technology, their latest product release marks a new chapter in their legacy of excellence.

Company News & Blog

Durable and Efficient Link Chain for Conveyors - The Latest in Conveyor Technology

Conveyor Link Chain Offers Innovative Solutions for Material Handling NeedsAs industries continue to evolve and grow, the need for efficient and reliable material handling solutions becomes increasingly important. This is where Conveyor Link Chain, a leading provider of conveyor chain systems, comes into play. With a strong focus on innovation and customer satisfaction, Conveyor Link Chain has rapidly become a trusted partner for businesses looking to streamline their material handling processes.Founded in 1999, Conveyor Link Chain has been at the forefront of developing and manufacturing high-quality conveyor chains for a wide range of industries, including automotive, food and beverage, pharmaceuticals, and more. The company's commitment to excellence and continuous improvement has enabled them to offer a diverse range of products that meet the unique needs of their customers.One of the key factors that sets Conveyor Link Chain apart from its competitors is its dedication to innovation. The company's team of experienced engineers and technicians are constantly working on developing new and improved conveyor chain systems that leverage the latest technologies and manufacturing processes. This commitment to innovation has allowed Conveyor Link Chain to stay ahead of the curve and consistently deliver state-of-the-art solutions to their clients.In addition to its focus on innovation, Conveyor Link Chain places a strong emphasis on customer satisfaction. The company takes a collaborative approach to working with its clients, taking the time to understand their specific material handling needs and providing customized solutions that align with their operational requirements. With a strong emphasis on after-sales support and service, Conveyor Link Chain ensures that its customers can rely on their conveyor chain systems for years to come.One of the standout products offered by Conveyor Link Chain is its range of [specific product name] conveyor chains, which have been designed to meet the rigorous demands of modern material handling applications. These chains are engineered to deliver exceptional performance, reliability, and durability, making them an ideal choice for businesses looking to optimize their material handling processes.Furthermore, Conveyor Link Chain's commitment to sustainability sets it apart from its competitors. The company places a strong emphasis on developing conveyor chain systems that are energy-efficient and environmentally friendly, helping businesses reduce their carbon footprint and contribute to a more sustainable future.With a strong track record of success and a growing list of satisfied customers, Conveyor Link Chain has positioned itself as a trusted partner for businesses looking to enhance their material handling capabilities. The company's dedication to innovation, customer satisfaction, and sustainability has made it a go-to choice for businesses across a wide range of industries.Looking ahead, Conveyor Link Chain is committed to continuing its tradition of excellence and further expanding its product offerings to meet the evolving needs of the material handling industry. With a strong focus on research and development, the company aims to introduce even more advanced conveyor chain systems that will set the standard for performance and reliability in the years to come.In conclusion, Conveyor Link Chain is a company that is truly dedicated to providing innovative and effective material handling solutions to its customers. With a focus on innovation, customer satisfaction, and sustainability, the company has established itself as a leader in the field of conveyor chain systems. As businesses continue to seek ways to optimize their material handling processes, Conveyor Link Chain stands ready to meet their needs with cutting-edge solutions that deliver results.

Ultimate Guide to Choosing the Right Roller Sizes for Your Chain

Chain Roller SizesChain rollers are an important component of conveyor systems, providing smooth and efficient movement of materials in various industries. It is essential to have the right chain roller size to ensure that the conveyor system operates at its optimal capacity. Choosing the correct size for your application can improve the performance and longevity of your conveyor system.Chain rollers come in a variety of sizes and designs to meet the specific needs of different conveyor systems. Standard roller sizes range from 1 inch to 3 inches in diameter, with custom sizes available for special applications. The size of the chain roller is determined by the width and weight of the material being conveyed, as well as the speed and incline of the conveyor system.When selecting the chain roller size for a conveyor system, it is important to consider the following factors:1. Material weight and width: Heavier and wider materials will require larger chain rollers to provide adequate support and smooth movement along the conveyor system.2. Speed and incline: Higher speeds and steeper inclines will require larger chain rollers to ensure that the materials can be conveyed smoothly and efficiently without causing excessive wear and tear on the conveyor system.3. Environmental conditions: Harsh environments such as extreme temperatures, moisture, and chemicals may require special materials and sizes for chain rollers to ensure durability and longevity.[Company Name] is a leading manufacturer of conveyor systems and components, including chain rollers. With a focus on quality and innovation, [Company Name] offers a wide range of chain roller sizes to meet the diverse needs of their customers. Their chain rollers are designed to provide smooth and reliable operation, even in the most demanding applications.The company’s chain rollers are available in various materials, including steel, stainless steel, and plastic, to accommodate different environmental conditions and material handling requirements. They also offer custom design and manufacturing services to create chain rollers that meet specific size and performance needs for unique conveyor systems.[Company Name]’s chain rollers are engineered to provide low-friction, high-impact resistance, and long-lasting performance. Their precision design and manufacturing process ensure that each chain roller meets the highest quality standards for reliable and efficient operation in a wide range of industries, including food processing, automotive, packaging, and manufacturing.In addition to standard sizes, [Company Name] also offers a range of accessories and options for chain rollers, including bearings, seals, and lubrication systems, to further enhance the performance and longevity of conveyor systems.As the demand for efficient and reliable material handling solutions continues to grow, [Company Name] remains at the forefront of innovation, continually developing and improving their chain rollers and other conveyor components to meet the evolving needs of their customers.With a focus on quality, durability, and performance, [Company Name]’s chain rollers are an ideal choice for businesses looking to optimize their conveyor systems and maximize productivity.In conclusion, selecting the right chain roller size is crucial for the efficient and reliable operation of conveyor systems. With a wide range of sizes and materials available, businesses can choose the best chain roller for their specific application to ensure smooth material handling and prolonged conveyor system life. As a leading manufacturer of conveyor components, [Company Name] offers a comprehensive range of chain roller sizes and options to meet the diverse needs of their customers, backed by a commitment to quality, innovation, and customer satisfaction.

High-Efficiency Roller Chain Conveyor for Industrial Use

Roller Chain Conveyor system has become an integral part of many industries around the world. This innovative technology has significantly improved the efficiency, productivity, and safety of material handling processes. One of the leading companies in the industry, {}, has been at the forefront of developing and manufacturing high-quality roller chain conveyor systems for a wide range of applications.Established in the early 2000s, {} has amassed a wealth of experience and expertise in the design and production of roller chain conveyor systems. The company's commitment to delivering superior quality products and exceptional customer service has earned them a solid reputation in the industry. With a state-of-the-art manufacturing facility and a team of skilled engineers and technicians, {} continues to be a trusted provider of conveyor solutions for various industries, including automotive, food and beverage, logistics, and many others.One of the key advantages of {}'s roller chain conveyor systems is their durability and reliability. The company uses high-quality materials and precision engineering to ensure that their conveyor systems can withstand the rigors of heavy-duty industrial applications. This means that customers can rely on {}'s products to deliver consistent performance and durability, even in the most demanding operating conditions.In addition to their robust design, {}'s roller chain conveyor systems are also designed for optimal efficiency and productivity. The company offers a wide range of conveyor configurations, including straight conveyors, curved conveyors, and incline conveyors, to suit the specific needs of their customers. Whether it's transporting heavy pallets, large crates, or delicate components, {}'s conveyor systems are engineered to deliver smooth and reliable material handling, minimizing downtime and maximizing throughput.Furthermore, {} places a strong emphasis on safety in the design of their roller chain conveyor systems. The company ensures that all of their products comply with industry safety standards and regulations, providing customers with peace of mind and confidence in the safety of their operations. This commitment to safety is reflected in the various safety features incorporated into {}'s conveyor systems, such as protective guarding, emergency stop systems, and safety interlocks.Another notable aspect of {}'s roller chain conveyor systems is their versatility and adaptability. The company's engineering team works closely with customers to understand their unique material handling challenges and develop customized conveyor solutions to address their specific requirements. This collaborative approach has allowed {} to successfully implement conveyor systems in a wide range of industries, providing tailored solutions that enhance efficiency and productivity.In addition to their commitment to product quality and customer satisfaction, {} also offers comprehensive aftersales support and maintenance services for their roller chain conveyor systems. The company's team of technical experts is readily available to provide troubleshooting assistance, spare parts, and maintenance services, ensuring that customers can maximize the lifespan and performance of their conveyor systems.Looking ahead, {} continues to innovate and expand their range of roller chain conveyor systems, incorporating the latest technologies and advancements to meet the evolving needs of their customers. Whether it's enhancing automation, improving energy efficiency, or integrating smart monitoring and control systems, {} is dedicated to staying at the forefront of conveyor technology and delivering cutting-edge solutions to their customers.In summary, {} has established itself as a leading provider of roller chain conveyor systems, delivering durable, efficient, and safe material handling solutions to industries around the world. With a focus on quality, innovation, and customer satisfaction, {} is well-positioned to continue driving advancements in conveyor technology and providing exceptional value to their customers.

Durable Industrial Roller Chain for Heavy-Duty Applications

Industrial Roller Chain, known for its high-quality products and reliable performance, has been a key player in the industrial machinery sector for many years. With a strong focus on innovation and technological advancement, the company has continuously set new industry standards and has established itself as a leader in the field.Founded in the early 1950s, Industrial Roller Chain has grown from a small local business to a global industry powerhouse. The company's commitment to quality and customer satisfaction has been a driving force behind its success. With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, Industrial Roller Chain has consistently delivered top-notch products to its customers around the world.The company's wide range of industrial roller chains caters to various industries, including automotive, manufacturing, food processing, and agriculture. These chains are designed to withstand the most demanding applications and provide reliable and efficient performance under extreme conditions. From standard roller chains to specialty chains for specific industries, Industrial Roller Chain offers a comprehensive portfolio of products that meet the diverse needs of its customers.In addition to its standard product offerings, Industrial Roller Chain also provides customized solutions to meet specific customer requirements. The company's team of experienced engineers works closely with clients to develop tailor-made chain solutions that address unique challenges and deliver optimal performance. This commitment to customization sets Industrial Roller Chain apart from its competitors and has earned the trust and loyalty of a diverse customer base.Industrial Roller Chain's dedication to innovation is evident in its continuous investment in research and development. The company is constantly exploring new technologies and materials to enhance the performance and durability of its products. This relentless pursuit of innovation has enabled Industrial Roller Chain to introduce cutting-edge chain designs that deliver superior results and exceed industry expectations.Furthermore, Industrial Roller Chain is committed to sustainability and environmental responsibility. The company adheres to stringent environmental standards in its manufacturing processes and actively seeks ways to reduce its carbon footprint. By implementing eco-friendly practices and using energy-efficient technologies, Industrial Roller Chain has not only minimized its environmental impact but has also set an example for the industry as a whole.As part of its ongoing commitment to excellence, Industrial Roller Chain places a strong emphasis on quality control and assurance. Every product undergoes rigorous testing and inspection to ensure that it meets the company's high standards for performance and reliability. This meticulous attention to detail has earned Industrial Roller Chain a reputation for delivering products of unmatched quality and consistency.Moreover, Industrial Roller Chain is dedicated to providing exceptional customer service. The company's team of knowledgeable and responsive professionals is always ready to assist clients with their needs, whether it's product selection, technical support, or after-sales service. Industrial Roller Chain's customer-centric approach has fostered long-lasting relationships with its clients and has positioned the company as a trusted partner in the industry.Looking ahead, Industrial Roller Chain remains committed to pushing the boundaries of innovation and setting new benchmarks for excellence in the industrial machinery sector. The company's relentless pursuit of quality, customization, sustainability, and customer satisfaction will continue to drive its success and solidify its position as a global leader in the industry.In conclusion, Industrial Roller Chain's unwavering dedication to quality, innovation, and customer satisfaction has propelled it to the forefront of the industrial machinery sector. With a strong focus on customization, sustainability, and superior performance, the company has set new industry standards and earned the trust of a diverse customer base. As Industrial Roller Chain continues to push the boundaries of innovation and excellence, it is poised to maintain its leadership position in the global market for years to come.

High-Quality Roller Chain for Smooth Operation

Chain With Rollers Upgrades Efficiency and Performance for Industrial ApplicationsChain with rollers, a crucial component in various industrial machinery, plays a pivotal role in enhancing efficiency, productivity, and overall performance. As industrial processes become more advanced, the demand for high-quality chain with rollers has significantly increased. In response to this growing demand, {Company}, a leading manufacturer of industrial components, has introduced a new line of chain with rollers designed to meet the evolving needs of industrial applications.With a strong focus on innovation and technology, {Company} has been at the forefront of developing cutting-edge solutions for the industrial sector. The company's commitment to research and development has led to the creation of a range of high-precision, durable, and high-performance chain with rollers that are designed to withstand heavy loads, high speeds, and harsh operating conditions.The newly introduced chain with rollers is engineered to deliver exceptional reliability, smooth operation, and reduced maintenance requirements, making it an ideal choice for a wide range of industrial applications. By incorporating advanced materials and precision engineering, {Company} has succeeded in enhancing the performance and longevity of its chain with rollers, ultimately contributing to improved efficiency and cost savings for industrial users.One of the key features of the new chain with rollers is its enhanced wear resistance, which allows for prolonged use without compromising performance. This is particularly beneficial for industries with high-frequency operations, where the durability of components is essential for uninterrupted production processes. Additionally, the precision design of the rollers ensures smooth engagement with sprockets, resulting in reduced noise, vibration, and energy consumption, further contributing to overall operational efficiency.{Company}'s dedication to quality and excellence is reflected in the rigorous testing and quality control processes that all its products undergo. The new line of chain with rollers has been subjected to comprehensive testing to validate its performance, durability, and suitability for diverse industrial applications. As a result, customers can have full confidence in the reliability and effectiveness of {Company}'s chain with rollers for their specific requirements.Furthermore, {Company} understands the importance of customization in meeting the unique needs of different industries. As such, the newly introduced chain with rollers can be tailored to specific requirements, including size, strength, and surface treatments, ensuring a perfect fit for various industrial machinery and equipment. This versatility and flexibility further position {Company} as a trusted partner for businesses seeking tailored solutions for their industrial operations.The introduction of the new line of chain with rollers represents {Company}'s ongoing commitment to driving innovation and delivering value to its customers. By continuously investing in research, development, and advanced manufacturing processes, {Company} is well-positioned to meet the evolving demands of the industrial sector and support the growth and success of businesses across various industries.In conclusion, the launch of the new chain with rollers by {Company} marks a significant advancement in the realm of industrial components. With its focus on quality, durability, and customization, {Company} has solidified its position as a leading provider of high-performance chain with rollers tailored to the specific needs of industrial applications. As industries continue to evolve and expand, {Company} remains dedicated to supporting the efficiency, productivity, and success of its customers through innovative and reliable solutions.

Essential Guide to Conveyor Chain Sprockets: Everything You Need to Know

[Company Introduction] As a leading manufacturer in the industrial machinery sector, our company has been specializing in the production and distribution of high-quality conveyor chain sprockets for over two decades. With a strong commitment to innovation and customer satisfaction, we have established ourselves as a reliable and trusted supplier to a wide range of industries including automotive, manufacturing, and logistics.Our state-of-the-art manufacturing facilities, coupled with a dedicated team of engineers and technicians, enable us to deliver superior products that meet the highest quality standards. Our extensive product range caters to various conveyor systems, offering solutions for different load capacities and operational requirements.In line with our commitment to excellence, we continuously invest in research and development to enhance the performance and durability of our conveyor chain sprockets. Our stringent quality control measures ensure that each product meets our stringent specifications before it reaches our customers.[News Content]Conveyor Chain Sprocket: The Backbone of Efficient Material Handling SystemsIn the world of material handling and industrial machinery, conveyor systems play a crucial role in the efficient transportation of goods and materials within manufacturing and distribution facilities. At the heart of these systems are conveyor chain sprockets, which are essential components that drive the movement of the conveyor chains. These sprockets are designed to withstand heavy loads, high speeds, and harsh operating conditions, making them a critical part of a smooth and reliable material handling process.Our company, a leading manufacturer of conveyor chain sprockets, understands the significance of these components in ensuring the seamless operation of conveyor systems. With our meticulous attention to detail and commitment to quality, we have earned a reputation for delivering sprockets that excel in performance and durability.The design and construction of our conveyor chain sprockets are tailored to meet the diverse needs of our customers across various industries. From standard sprockets to custom-made solutions, we offer a comprehensive range of options to accommodate different conveyor configurations and operational requirements. Our sprockets are precision-engineered to provide smooth and efficient power transmission, minimizing wear and tear on the conveyor chains and ensuring a longer service life.We utilize advanced manufacturing techniques and materials to produce conveyor chain sprockets that can withstand the rigors of heavy-duty applications. Whether it's high-temperature environments, corrosive substances, or heavy loads, our sprockets are built to endure the challenges of industrial operations while maintaining their reliability and performance.Furthermore, we are committed to innovation and continuous improvement in our product offerings. Our research and development initiatives focus on enhancing the design and functionality of our conveyor chain sprockets, incorporating technological advancements to optimize their efficiency and resilience. By staying at the forefront of industry trends and technological developments, we strive to provide our customers with cutting-edge solutions that address their evolving needs in material handling and conveyance.In addition to our dedication to product excellence, we also prioritize customer satisfaction and support. Our team of experienced professionals is readily available to provide technical expertise and guidance on choosing the right conveyor chain sprockets for specific applications. We understand the importance of seamless integration and reliable performance in conveyor systems, and we are committed to assisting our customers in achieving optimal operational efficiency through our high-quality sprockets.In conclusion, conveyor chain sprockets are integral components that underpin the functionality and effectiveness of material handling systems in various industries. Our company's unwavering commitment to producing superior sprockets that deliver exceptional performance, durability, and compatibility with diverse conveyor setups has positioned us as a trusted partner for businesses seeking reliable solutions for their material conveyance needs. With our dedication to innovation and customer satisfaction, we remain at the forefront of the industry, continuously striving to set new standards for excellence in conveyor chain sprocket technology.

Top Stainless Steel Conveyor Chains for Smooth Material Handling

Stainless Steel Conveyor Chain has always been essential in various industries, including food processing, pharmaceuticals, and manufacturing. The durable and reliable nature of stainless steel makes it an ideal material for conveyor chains, as it can withstand harsh environmental conditions and high temperatures while maintaining its integrity. Recently, {Company Name} has introduced a new line of stainless steel conveyor chains that are set to revolutionize the industry.{Company Name} is a leading manufacturer of conveyor chains and other industrial products. With years of experience and a strong commitment to quality, they have gained a reputation for producing high-performance and long-lasting products. Their latest line of stainless steel conveyor chains is no exception, as it promises to deliver exceptional performance and durability in even the most demanding environments.The new stainless steel conveyor chains from {Company Name} are made from high-grade stainless steel, ensuring corrosion resistance and longevity. This makes them suitable for use in industries where hygiene and cleanliness are of utmost importance, such as food and beverage processing. The chains are also designed to withstand extreme temperatures, making them ideal for use in ovens, furnaces, and other high-heat applications.One of the key features of the new stainless steel conveyor chains from {Company Name} is their precision engineering. Each chain is meticulously crafted to ensure smooth operation and minimal wear and tear. This not only extends the lifespan of the chains but also reduces maintenance and replacement costs for businesses.Moreover, {Company Name} offers a wide range of stainless steel conveyor chains to meet the specific needs of different industries. Whether it's a straight-running, side-flexing, or multiflex chain, they have a solution for every application. Their chains are also available in various sizes and configurations, allowing for easy integration into existing conveyor systems.In addition to the superior quality of their products, {Company Name} is also known for their exceptional customer service. They work closely with their clients to understand their unique requirements and provide customized solutions that meet or exceed their expectations. This personalized approach has earned them the trust and loyalty of countless businesses across the globe.As part of their commitment to sustainability, {Company Name} also ensures that their stainless steel conveyor chains are manufactured using eco-friendly processes and materials. This not only reduces the environmental impact of their products but also aligns with the green initiatives of many modern businesses.Looking ahead, {Company Name} is continuously innovating and refining their products to stay ahead of the curve. They are committed to pushing the boundaries of what is possible and setting new standards for quality and performance in the industry.In conclusion, {Company Name}'s new line of stainless steel conveyor chains is a game-changer for industries that rely on durable and reliable conveyor systems. With their unparalleled quality, precision engineering, and commitment to customer satisfaction, {Company Name} has once again demonstrated why they are a leader in the industry. Businesses can now harness the power of these revolutionary chains to optimize their operations and achieve new levels of efficiency and productivity.

Understanding the Importance of Roller Chains in Industrial Applications

Established in 1917, Metric Roller Chain has been a leading manufacturer and supplier of high-quality roller chains for various industries around the world. With a commitment to excellence and innovation, the company has become a trusted name in the industry, providing reliable and durable products to meet the diverse needs of its customers.Metric Roller Chain has recently introduced a new line of roller chains that are designed to deliver superior performance and longevity. These chains are manufactured using the latest technology and highest quality materials to ensure maximum strength, durability, and precision.The new roller chains are designed to meet the growing demand for high-performance chains in industries such as agriculture, mining, construction, and industrial automation. With a focus on quality and reliability, Metric Roller Chain is dedicated to providing its customers with the best products to help them achieve their operational goals.The company's commitment to innovation and continuous improvement has positioned it as a leader in the industry, and the introduction of the new roller chains is a testament to its dedication to providing the highest quality products to its customers.In addition to its new product line, Metric Roller Chain also offers a comprehensive range of other chain products such as standard roller chains, heavy-duty chains, corrosion-resistant chains, and specialty chains. With a wide range of products to choose from, customers can find the perfect solution to meet their specific needs and requirements.Metric Roller Chain takes great pride in its ability to provide exceptional customer service and support. The company's team of experienced professionals is dedicated to helping customers find the best chain solutions for their applications, and its commitment to customer satisfaction is evident in everything it does.With a global network of distributors and partners, Metric Roller Chain is able to serve customers around the world, providing them with the products they need, when they need them. The company's extensive distribution network ensures that customers can access its high-quality products no matter where they are located.As a company that values innovation, quality, and customer satisfaction, Metric Roller Chain is continuously investing in research and development to stay ahead of the curve. By staying at the forefront of technological advancements and industry trends, the company is able to offer cutting-edge products that meet the evolving needs of its customers.Metric Roller Chain is proud to be a trusted partner for businesses across a wide range of industries, and its new line of roller chains is a testament to its commitment to providing the best products on the market. With a focus on quality, reliability, and customer satisfaction, the company is poised to continue its success and maintain its position as a leader in the industry for years to come.In conclusion, Metric Roller Chain's introduction of its new line of roller chains further reinforces its position as a leading manufacturer and supplier of high-quality chain products. With a commitment to excellence and innovation, the company is dedicated to providing its customers with the best products to meet their diverse needs. By focusing on quality, reliability, and customer satisfaction, Metric Roller Chain is well-positioned to maintain its leadership in the industry and continue serving businesses around the world with its exceptional products and services.

Top Links for Chains: A Comprehensive Guide

D Links For Chains, a renowned manufacturer and supplier of high-quality chains and link accessories, has recently introduced a new range of innovative chain links designed to meet the needs of various industries.With over [number of years] years of experience in the industry, D Links For Chains has built a solid reputation for delivering superior products that are not only durable and reliable, but also customizable to meet specific requirements. The company specializes in producing chains for a wide range of applications, including industrial machinery, lifting equipment, agricultural machinery, and more.The new range of chain links introduced by D Links For Chains encompasses a variety of styles and sizes to cater to different needs. Whether it's for heavy-duty industrial use or light-duty applications, the company offers chain links that are designed to withstand the rigors of demanding environments while providing optimal performance.One of the key highlights of the new range is the incorporation of advanced materials and manufacturing techniques to enhance the strength and durability of the chain links. This ensures that the products meet or exceed industry standards for quality and reliability.In addition to standard chain links, D Links For Chains also offers custom solutions tailored to specific customer requirements. This includes the ability to modify chain link designs, sizes, and materials to accommodate unique application needs.The company's commitment to delivering high-quality products is further exemplified by its strict adherence to quality control measures throughout the production process. Each chain link undergoes rigorous testing to ensure that it meets the company's strict quality criteria before being made available to customers.Furthermore, D Links For Chains places a strong emphasis on customer satisfaction and support, offering comprehensive technical assistance and guidance to help customers select the right chain links for their specific applications. This level of personalized service sets the company apart as a trusted partner for businesses seeking reliable chain solutions.The introduction of the new range of chain links by D Links For Chains is expected to address the growing demand for durable and efficient chains in various industries. As businesses continue to seek reliable components to optimize their operations, the company's latest offering is poised to make a significant impact in the market."We are thrilled to introduce our new range of chain links, which represents the culmination of extensive research and development efforts aimed at delivering top-notch products to our customers," said [Spokesperson's Name], [Position] at D Links For Chains. "We believe that these innovative chain links will not only meet but exceed the expectations of our customers, and we are committed to providing unparalleled support to ensure their success."As the industry continues to evolve, D Links For Chains remains at the forefront of innovation, consistently striving to meet the evolving needs of its customers and deliver cutting-edge solutions that set new benchmarks for quality and performance.For businesses seeking reliable and durable chain links for their operations, D Links For Chains stands out as a dependable provider with a proven track record of excellence. With its latest range of innovative chain links, the company reaffirms its commitment to delivering exceptional products that drive success for its customers.

Different Types of Sprocket Chains: A Comprehensive Guide

The use of sprocket chains is essential in various industries, including construction, automotive, and manufacturing. These chains are critical components in machinery and equipment, providing the necessary power transmission for smooth and efficient operation.There are several types of sprocket chains available, each designed for specific applications and operating conditions. Let's take a closer look at some of the common types of sprocket chains and their uses.1. Roller Chains: Roller chains are one of the most common types of sprocket chains and are used in a wide range of industrial applications. These chains consist of cylindrical rollers that are connected by link plates. Roller chains are known for their high strength and durability, making them suitable for heavy-duty applications such as conveyor systems, hoists, and power transmission equipment.2. Silent Chains: Silent chains, also known as inverted tooth chains, are designed to operate quietly and smoothly, making them ideal for use in high-speed and high-torque applications. These chains feature a unique design with special profiled link plates that engage with sprocket teeth, minimizing noise and vibration during operation. Silent chains are commonly used in motorcycles, automobiles, and agricultural machinery.3. Leaf Chains: Leaf chains, also referred to as forklift chains, are specifically designed for lifting applications. These chains consist of link plates that are connected by pins and are known for their high tensile strength and resistance to shock loading. Leaf chains are commonly used in forklift trucks, cranes, and other material handling equipment.4. Engineering Class Chains: Engineering class chains are heavy-duty chains that are designed for use in demanding industrial applications. These chains are commonly used in mining, forestry, and construction equipment, where they are exposed to harsh operating conditions, including high loads, abrasive materials, and environmental contaminants. Engineering class chains are available in a variety of configurations, including drive chains, conveyor chains, and drag chains.It is important to note that the selection of the right type of sprocket chain is crucial to ensure optimal performance and reliability in specific applications. Factors such as load capacity, speed, operating environment, and maintenance requirements should be carefully considered when choosing a sprocket chain for a particular application.As a leading manufacturer of sprocket chains, {} is committed to providing high-quality products that meet the needs of our customers across various industries. With our extensive experience and expertise in chain technology, we offer a wide range of sprocket chains that are designed to deliver superior performance, durability, and reliability in even the most challenging operating conditions.Our state-of-the-art manufacturing facilities and stringent quality control processes ensure that our sprocket chains meet the highest industry standards and specifications. We work closely with our customers to understand their specific requirements and provide customized solutions to meet their unique application needs.In addition to sprocket chains, {} also offers a comprehensive range of power transmission products, including roller chains, sprockets, couplings, and more. Our commitment to innovation and continuous improvement drives us to develop advanced chain technologies that deliver enhanced performance and value to our customers.Whether you are looking for a standard sprocket chain or a custom-engineered solution, {} has the expertise and capabilities to meet your needs. Contact us today to learn more about our sprocket chains and other power transmission products. Let us help you find the right solution for your application.